In the domain of gathering, the drive for capability, exactness, and versatility is resolute. Organizations are ceaselessly looking for strategies that fulfill their creation needs as well as surpass their assumptions in quality and cost adequacy. Among the different assembling procedures accessible today, infusion forming stands apart as a critical innovation that has changed the scene of creation. This article digs into the many subtleties of infusion forming, investigates its advantages, and introduces 3ERP’s injection molding services as a solution for modern manufacturing challenges.

Understanding Injection Molding

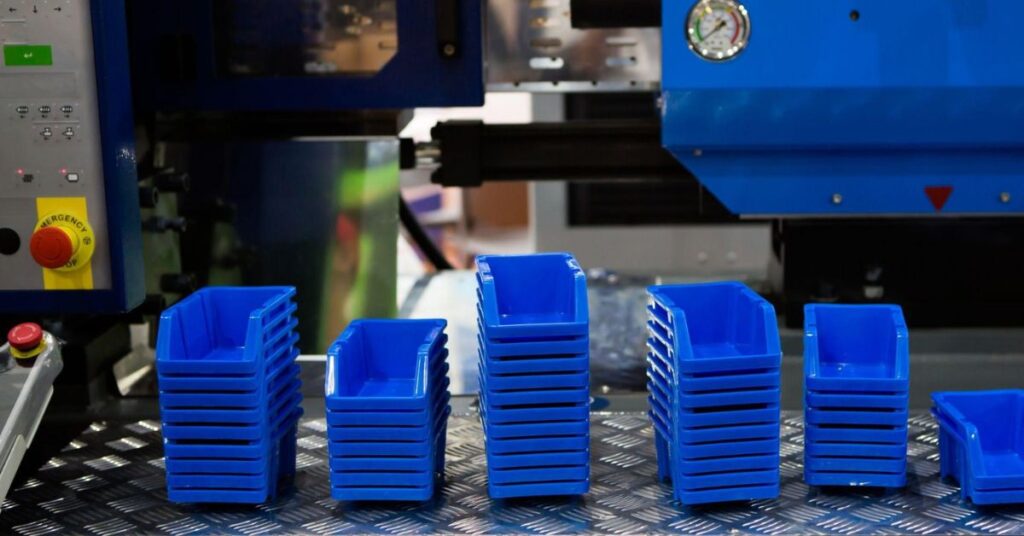

Infusion forming is a profoundly flexible and proficient assembling process used to create a large number of plastic parts and parts. The interaction includes infusing liquid material — ordinarily plastic — into a form pit under high tension. When the material cools and cements, the shape is opened to deliver the completed part. This technique considers the production of mind boggling shapes and high accuracy, making it ideal for delivering high-volume leaves behind reliable quality.

The injection molding process can be broken down into several key stages:

- Material Planning: The initial step includes setting up the natural substance, generally plastic pellets or granules, which are taken care of in the infusion shaping machine. The material is warmed to a liquid state to make it reasonable for infusion into the shape.

- Infusion: The liquid plastic is infused into the shape depression through a spout under high tension. This guarantees that the material fills the form totally and takes the state of the pit.

- Cooling: When the shape is filled, the material is permitted to cool and cement. This step is urgent as it decides the last properties of the part, including its solidarity and layered exactness.

- Send off: Resulting to cooling, the shape is opened, and the established part is shot out. Depending upon the multifaceted nature of the structure, additional advances, for instance, overseeing or finishing may be required.

- Assessment and Quality Control: The last step incorporates checking on the formed parts to ensure they meet the important points of interest and quality standards. Any defects or abnormalities are recognized and tended to.

Advantages of Injection Molding

Infusion shaping offers a few critical benefits that make it a favored decision for some makers:

- High Accuracy and Consistency: Infusion shaping gives great layered precision and repeatability, guaranteeing that each part created is reliable with the others. This accuracy is critical for applications where precise details are required.

- Cost-Viability for High Volumes: While the underlying arrangement costs for molds and apparatus can be high, the per-unit cost diminishes essentially with bigger creation runs. This makes infusion shaping profoundly savvy for creating huge amounts of parts.

- Plan Adaptability: The interaction considers the making of mind boggling shapes and unpredictable subtleties that would be testing or difficult to accomplish with other assembling strategies. This adaptability empowers fashioners to develop and push the limits of item plans.

- Material Flexibility: Mixture frivolity can be used with an enormous number of materials, including various kinds of plastics, metals, and composites. This adaptability ensures that creators can pick the best material for their specific application.

- Negligible Waste: The infusion shaping interaction is profoundly proficient, with insignificant material waste contrasted with different techniques. An overabundance of material is frequently reused and reused, adding to a more manageable assembling process.

Applications of Injection Molding

Infusion shaping is utilized across various enterprises because of its adaptability and productivity. A portion of the key applications include:

- Car Industry: Creation of parts, for example, dashboard boards, trim parts, and motor parts.

- Customer Merchandise: Assembling of family things, electronics fenced-in areas, and bundling.

- Clinical Gadgets: Making of exact clinical parts, including needles, vials, and demonstrative hardware.

- Aviation: Creation of lightweight and sturdy parts for airplanes and shuttles.

3ERP’s Injection Molding Services

As enterprises proceed to develop and request further developed assembling arrangements, 3ERP stands apart with its extensive infusion shaping administrations.3ERP’s injection molding services are designed to meet the diverse needs of modern manufacturers, offering both standard and customized solutions.

Expertise and Capabilities

3ERP’s group of specialists gets broad experience in infusion forming, guaranteeing that clients get first-rate administration and great items. The organization uses best-in-class apparatus and state-of-the-art innovation to convey exact and solid outcomes. Key parts of 3ERP’s infusion forming administrations include:

- Custom Trim Arrangements: 3ERP offers fitted answers to meet explicit client prerequisites, including custom shape plan and material determination. This adaptability permits clients to accomplish the ideal presentation and feel for their items.

- Fast Prototyping: For clients requiring speedy completion times, 3ERP gives quick prototyping administrations. This takes into consideration quicker advancement and testing of item plans, assisting clients with putting up their developments for sale to the public all the more effectively.

- Quality Confirmation: 3ERP is focused on keeping up with elevated requirements of value all through the assembling system. Thorough quality control measures are set up to guarantee that each part meets the expected determinations and execution rules.

- Supportability: The organization underscores manageable works, including material reusing and proficient utilization of assets. This obligation to supportability lines up with the developing accentuation on ecological obligation in assembling.

Case Studies and Success Stories

3ERP has a history of effective tasks across different ventures, showing its capacity to deal with mind-boggling and high-volume infusion-forming necessities. Contextual investigations feature the organization’s capacity to convey great items on time and inside the financial plan, supporting its standing as a confident accomplice in the assembling area.

Future Trends in Injection Molding

The infusion forming industry is persistently developing, with headways in innovation and materials molding the eventual fate of assembling. A portion of the arising patterns include:

- High-level Materials: The advancement of better-than-ever materials, like elite execution polymers and composites, is extending the potential outcomes of infusion forming.

- Shrewd Assembling: The mix of computerized innovations and robotization is improving the productivity and accuracy of infusion forming processes. Shrewd assembling methods, like constant checking and prescient support, are turning out to be progressively predominant.

- Manageability Drives: There is a developing spotlight on maintainability in infusion shaping, with endeavors to decrease energy utilization, limit waste, and use eco-accommodating materials.

In Summary

Infusion forming is a foundation of current assembling, offering unrivaled accuracy, proficiency, and flexibility. As businesses always request complicated and great items, the upsides of infusion forming become progressively obvious. 3ERP’s infusion-shaping administrations epitomize the capability of this innovation, giving custom-made arrangements that satisfy the most noteworthy guidelines of value and execution. For producers looking for a solid accomplice in infusion shaping, 3ERP stands prepared to convey creative and viable arrangements that drive outcomes in the present serious market.

1 thought on “Revolutionising Manufacturing: An In-Depth Look at Injection Molding”