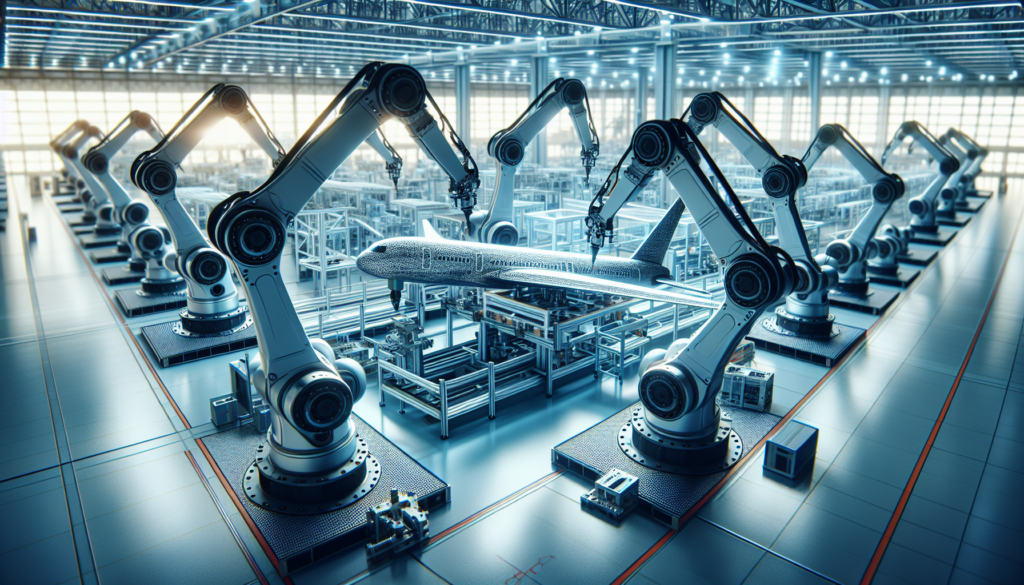

The airplane manufacturing industry, known for its high stakes and stringent quality requirements, has seen a transformative shift with the adoption of industrial automation. The integration of technologies like servo drive controllers has revolutionized the production process, enabling manufacturers to achieve unparalleled precision, efficiency, and safety. This article explores how industrial automation has reshaped airplane manufacturing, highlighting historical developments and the current state of technology.

Historical Overview of Automation in Airplane Manufacturing

The history of automation in airplane manufacturing can be traced back to the World War II era, a period marked by rapid technological advancements and an urgent need for mass production of military aircraft. During this time, companies such as Boeing began to introduce rudimentary forms of automation to increase output and ensure consistency in the manufacturing process. For instance, the use of jig fixtures to hold airplane parts in place during assembly was an early form of automation that helped standardize production and reduce manual labor.

As technology evolved, so did the automation systems used in airplane manufacturing. By the late 20th century, the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems marked a significant advancement, allowing for more complex and precise designs and the automation of numerous manufacturing tasks.

Integration of Servo Drive Controllers in Modern Manufacturing

Today, servo drive controllers are at the heart of modern airplane manufacturing automation systems. These devices are crucial for controlling the motion of machinery with high precision and flexibility. Servo drive controllers manage the operation of various automated systems, including robotic arms used for assembling parts, drilling machines for making precise holes, and automated painting and finishing processes.

1. Precision Assembly: In the assembly of airplanes, multiple components must be precisely aligned and assembled. Servo drive controllers manage the motors that control robotic arms, ensuring parts are manipulated and positioned with exact accuracy, which is crucial for maintaining the structural integrity and aerodynamics of the aircraft.

2. Automated Drilling and Riveting: Airplanes require thousands of rivets and fasteners. Servo-controlled drilling and riveting machines automate these tasks, performing them with high speed and precision. The accurate control offered by servo systems ensures that every rivet is placed correctly, which is essential for the aircraft’s durability and safety.

3. Painting and Coating: The application of protective coatings and paint on airplanes is another area where servo drive controllers, like the DKC02.3-040-7-FW play a significant role. These controllers ensure that paint robots apply consistent coats across the aircraft’s surface, enhancing appearance and resistance to environmental factors.

Benefits of Automation in Airplane Manufacturing

1. Enhanced Productivity: Automation allows for the continuous operation of production lines with minimal downtime. This is crucial in an industry where the demand for new aircraft is high, and production timelines are tight.

2. Superior Quality and Consistency: Automated processes ensure that each component and assembly meets strict aerospace manufacturing standards. This consistency is critical for safety and performance in the aviation industry.

3. Cost Efficiency: While the initial investment in automation technology can be high, the long-term benefits include reduced labor costs and increased production efficiency, leading to significant cost savings.

4. Improved Worker Safety: Automation reduces the need for human workers to perform dangerous tasks, such as high-precision drilling or painting, thus minimizing the risk of accidents and improving overall safety in manufacturing facilities.

Challenges and Future Directions

Despite its advantages, the integration of automation in airplane manufacturing presents challenges:

1. High Initial Costs: The cost of advanced automation systems, including servo drive controllers and robotic assembly lines, can be prohibitive, requiring significant capital investment.

2. Technical Complexity: Operating sophisticated automation systems requires a skilled workforce. Manufacturers must invest in training and development to ensure their staff can effectively manage these systems.

3. Maintenance and Upkeep: Automated systems require regular maintenance to perform optimally. This necessitates ongoing investment in maintenance staff and spare parts.

Looking ahead, the future of automation in airplane manufacturing is likely to be influenced by further advancements in AI and machine learning. These technologies could enable smarter automation systems that can predict maintenance needs, adapt to changes in production processes, and improve decision-making in the manufacturing workflow.

Conclusion

The integration of industrial automation, particularly the use of servo drive controllers, has fundamentally reshaped airplane manufacturing. From enhancing precision and efficiency to improving safety and reducing costs, the benefits of automation are clear. As the industry continues to evolve, staying at the forefront of technology will be crucial for manufacturers seeking to maintain competitiveness and meet the growing global demand for aircraft. The journey from early jig fixtures to today’s highly automated production lines illustrates the dynamic evolution of airplane manufacturing—a trajectory marked by continuous innovation and technological advancement.